Picture yourself standing on a lush green fairway, the sun casting a golden hue on the horizon.

Your heart races as you prepare to tee off, your trusty driver in hand.

But have you ever wondered what makes that little white ball soar through the air with such precision?

Here’s a quick answer to your question “Are golf balls hollow?”

Yes, golf balls are indeed hollow. The core of a golf ball, particularly in two-piece or multi-layered designs, contains a hollow space. This hollow construction allows for weight distribution optimization and enables manufacturers to fine-tune the performance characteristics of the ball, such as distance, spin, and feel.

Today, we embark on a journey to unravel the secrets behind the anatomy of golf balls, their unique design, and the reasons behind their hollow nature.

Anatomy of a Golf Ball

To understand whether golf balls are truly hollow, let’s explore their anatomy.

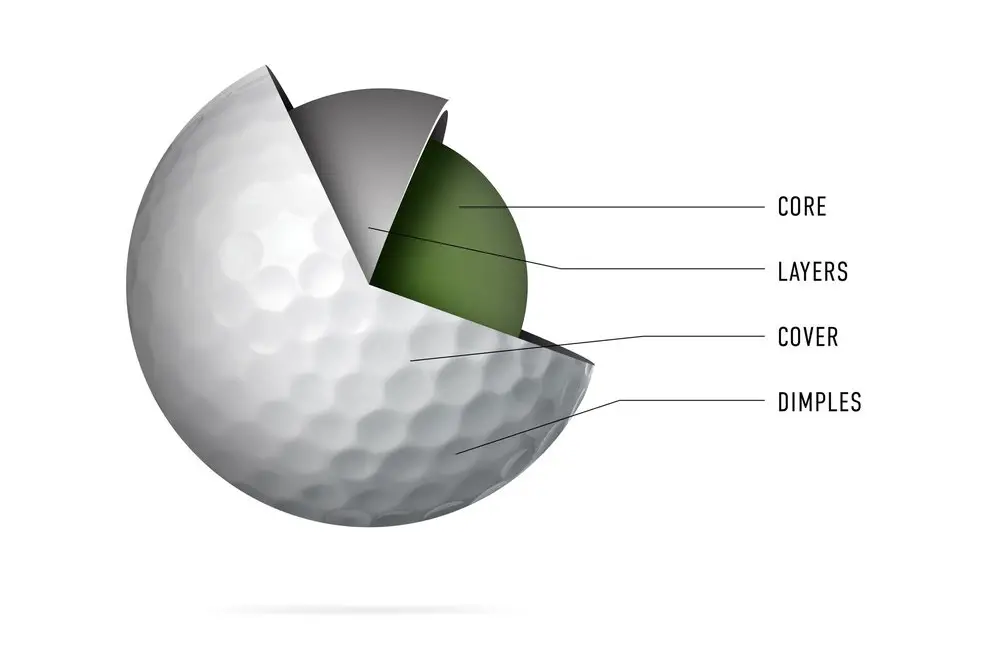

Golf balls consist of three main components:

- The cover

- The mantle

- The core.

Image Source: Golf Status

The cover, the outer layer of the ball, is often made of durable materials such as Surlyn or Urethane.

It acts as a protective shield against the forces encountered during a golf shot, safeguarding the ball’s integrity.

Beneath the cover lies the mantle, a layer responsible for enhancing ball control and optimizing performance.

Various materials, such as rubber or synthetic compounds, are used to create the mantle, which plays a crucial role in controlling the ball’s spin, trajectory, and responsiveness to different shots.

Finally, we arrive at the core, the innermost layer of the golf ball.

The core is where the magic happens, influencing the ball’s flight characteristics and compression.

Golf ball cores come in different constructions: one-piece, two-piece, and multi-layered. The one-piece construction consists of a solid core, while the two-piece and multi-layered constructions contain a hollow core.

Hollow vs. Solid Golf Balls

To better understand the concept of hollow golf balls, let’s first distinguish between hollow and solid objects.

Imagine holding an empty plastic bottle in one hand and a solid rubber ball in the other.

When you tap on the bottle, it produces a hollow sound due to the empty space inside.

In contrast, the rubber ball emits a solid thud because it lacks any hollow space within.

Applying this analogy to golf balls, it becomes clear that they are indeed hollow. Inside the core of a two-piece or multi-layered golf ball, there exists a vacant space, which imparts specific performance characteristics to the ball when struck.

This hollow construction allows golf ball manufacturers to fine-tune the weight distribution and optimize performance aspects such as distance, spin, and feel.

The Titleist Pro V1 golf ball is a popular choice among professional golfers.

Its multi-layered construction features a hollow core that helps generate maximum distance off the tee while maintaining exceptional control around the greens.

The hollow design of the core allows for a higher moment of inertia, resulting in less spin and improved accuracy.

The Manufacturing Process of Golf Balls

Now that we understand the concept of hollow golf balls, let’s delve into the manufacturing process.

Creating a golf ball requires intricate craftsmanship and attention to detail.

During production, the hollow design is achieved through a combination of materials and techniques.

The core, often made of synthetic rubber, undergoes a molding process to form its desired shape.

This shape allows for the creation of a hollow cavity, ensuring the core remains lightweight while maintaining structural integrity.

Advanced manufacturing technologies ensure consistency and precision, resulting in golf balls with consistent performance characteristics.

Golf Balls Regulation and Standards

Golf is a sport governed by rules and regulations to maintain fairness and integrity.

The governing bodies, such as the United States Golf Association (USGA) and the R&A, have established standards for golf balls.

These standards dictate factors such as size, weight, and construction to ensure fair play and a level playing field.

Hollow golf balls meet these regulations and are designed to optimize performance within the defined parameters.

Manufacturers conduct rigorous testing and adhere to strict quality control measures to ensure that their hollow golf balls meet the required standards.

This guarantees that golfers can confidently use these balls during competitive play, knowing that they comply with the rules of the game.

Comprehensive Golf Balls Comparison

To further illustrate the diversity of golf balls available in the market, let’s examine a comprehensive table chart showcasing different golf ball models, their design, characteristics, usage, and pros and cons.

This comparison will provide valuable insights to help you choose the right ball for your game:

| Golf Ball Model | Design | Characteristics | Usage | Pros | Cons |

|---|---|---|---|---|---|

| Titleist Pro V1 | Multi-layered | Hollow core, exceptional control, distance | Advanced golfers | Excellent control and distance | Higher price point, less forgiving |

| Callaway Chrome | Multi-layered | Dual-core construction, high energy transfer | All skill levels | Increased distance and feel | Slightly lower spin rates |

| TaylorMade TP5x | Multi-layered | Hollow core, maximum distance, low spin | Mid to high-handicap golfers | Impressive distance and accuracy | Not ideal for slower swing speeds |

| Bridgestone e6 | Two-piece | Solid core, reduced side spin | Mid to high handicap golfers | Straighter shots, forgiveness | Limited control around greens |

| Srixon Z-Star | Multi-layered | Hollow core, exceptional greenside control | All skill levels | Superior spin and control | Higher compression may not suit all golfers |

Golf Balls Design: Summary

Golf balls are indeed hollow, and their construction plays a vital role in shaping their performance on the course.

Understanding the anatomy of a golf ball, from the cover to the core, helps golfers appreciate the intricate engineering that goes into their design.

The hollow core design allows for weight distribution optimization, increased distance, and improved accuracy.

Manufacturers employ advanced manufacturing processes to create hollow golf balls, ensuring consistency and adherence to regulations set by governing bodies.

This guarantees that golfers can rely on the performance and compliance of the balls during competitive play.